| Brand | Vziman |

| Model NO. | 4000KVA 10KV Electric Furnace Transformer |

| Rated capacity | 4000KVA |

| Voltage grade | 10KV |

| Series | Electric Furnace Transformer |

Product overview:

Electric furnace transformer is a professional transformer planned according to various electric furnace working principle, load characteristics and operation characteristics.

It includes: arc furnace transformer for steelmaking, ladle refining furnace transformer, slag furnace transformer, mineral heat furnace transformer, power frequency furnace transformer and other communication furnace transformer and medium frequency induction furnace transformer, silicon carbide, graphitization furnace transformer and other DC furnace transformer.

Industrial furnace transformers are mainly divided into 3 types: resistance furnace transformers, arc furnace transformers and induction furnace transformers.

Hengfengyou electric furnace transformer production standards: one is according to the current provisions of China's standard planning and production of standard electric furnace transformer; The other is a new type of energy-saving furnace transformer developed and manufactured on the basis of Chinese standard furnace transformer.

Main applications:

In metallurgical industry, it is used for smelting high quality alloy copper and iron alloy.

In chemical industry, it is used to produce yellow phosphorus, calcium carbide, synthetic resin, etc.

Used in the melting of cast steel and cast iron in the mechanical industry.

High reliability of operation verification in more than 50 countries and regions around the world.

Products are mainly exported to East Asia, Central Asia, Southeast Asia, South America, North America and other markets and regions.

Implementation standard: IEC 60076 series.

Product advantagesl:

Leading technology:

Large capacity, low loss, more energy saving, the actual measurement is better than GB and IEC standards.

High pressure copper tape winding technology, improve lightning resistance.

Low voltage copper foil winding technology, high quality A class insulation material insulation, higher temperature resistance grade.

Small magnetic leakage, high mechanical strength, strong short circuit resistance.

Iron core 45° full oblique joint step laminated structure.

The shell:

Mitsubishi laser cutting machine and CNC punching, reducing, folding and other equipment to ensure the accuracy of processing.

ABB robot automatic welding, laser detection, to avoid leakage, qualified rate of 99.99998%.

Electrostatic spray treatment, 30 years of paint (coating corrosion resistance within 100h, hardness ≥0.4).

Fully sealed structure, maintenance-free and maintenance-free, normal operation life of more than 30 years.

The iron core:

The core material is high quality cold rolled grain oriented silicon steel sheet with mineral oxide insulation (from Baowu Steel Group, China).

Minimize loss level, no-load current and noise by controlling the cutting and stacking process of silicon steel sheet.

The iron core is specially reinforced to ensure the transformer structure is firm during normal operation and transportation.

winding:

Low voltage winding is made of high quality copper foil, excellent insulation resistance.

The high voltage windings are usually made of insulated copper wire, using the patented technology of Hengfengyou Electric.

Very good resistance to radial stress caused by short circuit.

High quality material:

Baowu Steel Group production of silicon steel sheet.

China produces high quality anaerobic copper.

CNPC (Kunlun Petroleum) High quality transformer oil (25#).

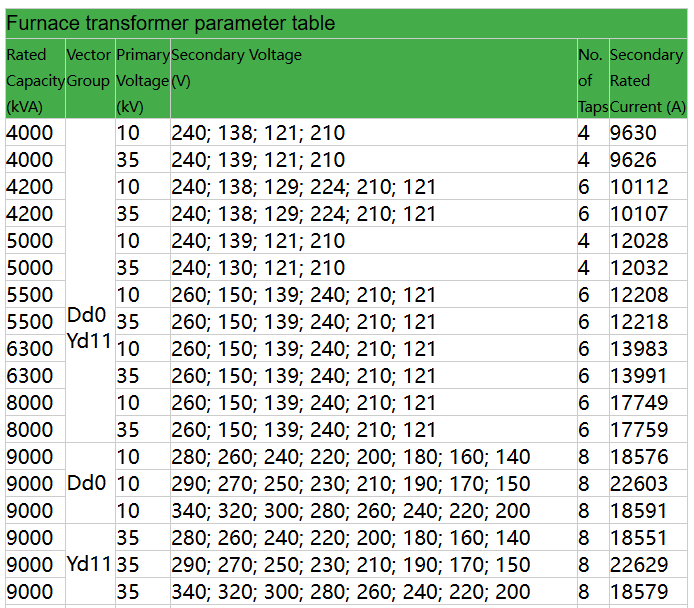

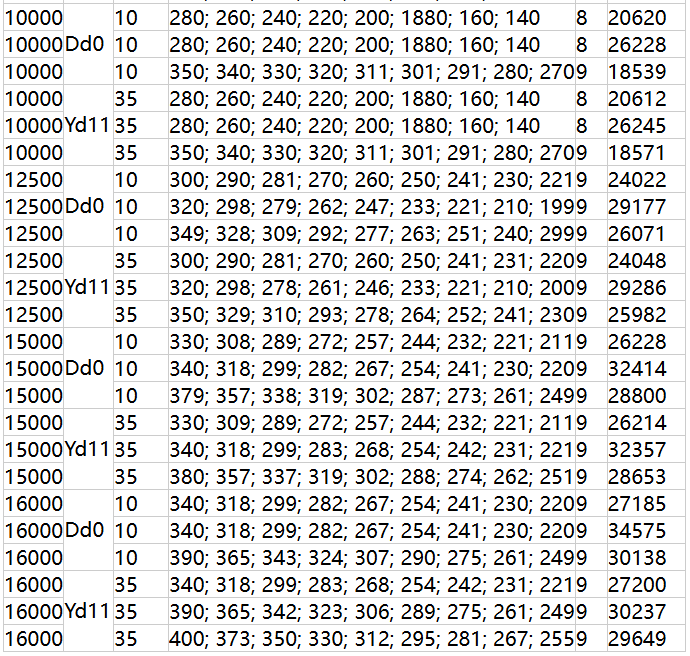

Product parameters:

Ordering instructions:

Main parameters of transformer (voltage, capacity, loss and other main parameters).

Transformer operating environment (altitude, temperature, humidity, location, etc.).

Other customization requirements.

Normal delivery period is 30 days.

Worldwide fast delivery.

What is an electric furnace transformer?

Furnace transformers are special - purpose transformers specifically used for electric arc furnaces, resistance furnaces, and other industrial electric furnaces. Its main function is to convert the high - voltage electrical energy provided by the power grid into low - voltage, high - current electrical energy suitable for the operation of electric furnaces. Furnace transformers are widely used in industries such as metallurgy, chemical engineering, and ceramics. The following are some key knowledge points of furnace transformers:

Definition and Characteristics:

Definition: A furnace transformer is a transformer specifically designed for electric furnaces, used to convert the high - voltage electrical energy of the power grid into low - voltage, high - current electrical energy suitable for the operation of electric furnaces.

Characteristics:

High Current: Furnace transformers can provide high current to meet the high - power requirements of electric furnace heating.

Low Voltage: The output voltage is usually low to meet the working requirements of electric furnaces.

High Heat Resistance: Furnace transformers need to work in high - temperature environments, so they have good heat - resistant properties.

High Reliability: Furnace transformers need to operate continuously for a long time, so they have high reliability and a long service life.

High Efficiency: Furnace transformers usually have high efficiency to reduce energy loss and improve energy efficiency.